- Catalogue: Products, Racking Accessories, Racking Systems, Radio Shuttle Racking

Product Description

The radio shuttle rack system is a high-density storage system composed of racks, trolleys, and forklifts. This high-efficiency storage method is to improve the utilization of warehouse space and bring customers a new storage option!

Working principle of radio shuttle rack:

Inventory: the forklift puts the goods on the front end of the guide rail of the rack lane, and the shuttle car operated by radio remote control can carry the pallet goods and run on the guide rail;

Pick-up: The shuttle car moves the pallets from the deepest part of the rack to the front of the rack, and uses a forklift to remove the palletized goods from the rack;

Mobile shuttle car: The shuttle car can be placed in different lanes by a forklift, and one shuttle car can be shared by multiple lanes. The number of shuttle cars is determined by comprehensive factors such as the depth of the roadway, the total amount of goods, the batch size of shipments, the frequency of shipments; transportation and storage racking systems. The space utilization rate is over 80%!

Specification of Radio Shuttle Rack

| ltem | The Specification | Equipmemnt Model | ||

| RGV-500 | RGV-1000 | RGV-1500 | ||

| 1、 | Suitable Pallets: | |||

| 1.1、 | Standard Pallet:L×W mm | W1200×D1000mm | ||

| 1.2、 | Size Range Available L×W mm | W1100~1250,D800~1100mm | ||

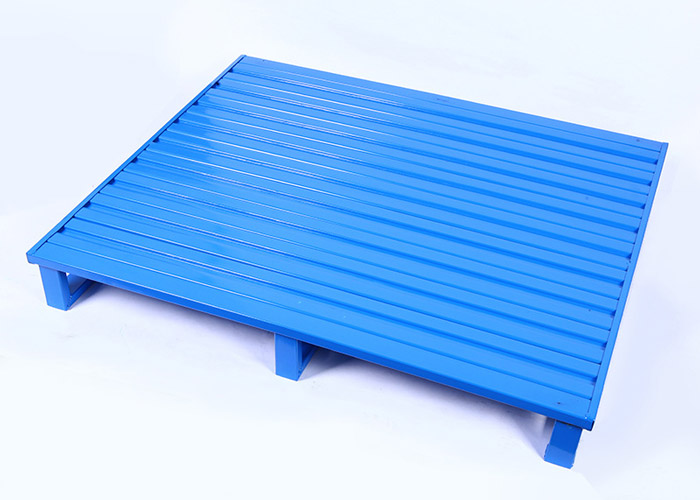

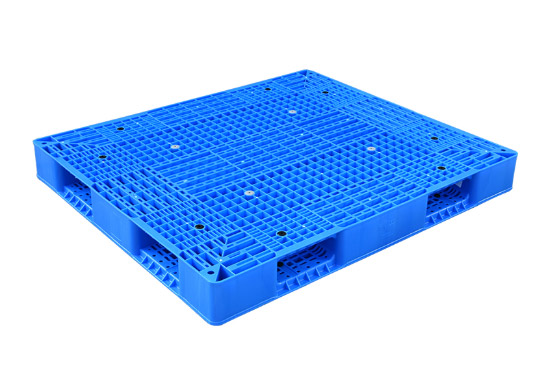

| 1.3、 | Styles of Pallet Bottom | Chuan type, Tian type | ||

| 1.4、 | Material of Pallet | Wood、Plastics、Steel | ||

| 1.5、 | Deflection of Pallet | Max 20mm | ||

| 2、 | Total Weight of Loading | Max 500kg | Max 1000kg | Max 1500kg |

| 3、 | Model of Running | Inside the rails | ||

| 4、 | Data of Running: | |||

| 4.1、 | Running without Loading | 1.1m/s | ||

| 4.2、 | Running with Max Loading | 0.9m/s | 0.7m/s | 0.5m/s |

| 5、 | Data of Lifting: | |||

| 5.1、 | Time of Single Lift | 1.1s | 1.3s | 1.5s |

| 5.2、 | Distance of Lift | 22mm | ||

| 5.3、 | Lift Height from Rail | 13mm | ||

| 6、 | Size of Equipment: | |||

| 6.1、 | Outside Dimensions LxWxHmm | L1100×W977×198mm | ||

| 6.2、 | Total Weight of Equipment | 242kg | 248kg | 260kg |

| 6.3、 | Plate Size of Equipment | L960×W85×T3mm,2Pcs | ||

| 6.4、 | Inner Width of Two Forks | 230mm | ||

| 6.5、 | Width of Single Forks | 236mm | ||

| 7、 | Driver Motor for Running | Lenze 24V 200W | ||

| 8、 | Wheels of Running | φ120mm Vulkollan | ||

| 9、 | Driver Motor for Lift | Lenze 24V 370W | ||

| 10、 | Battery Packs Capacity | BYD 2 set×2V 30AH | ||

| 11、 | Weight of Battery Packs | 2set×11kg | ||

| 12、 | Numbers of Charge discharge | 900 times | ||

| 13、 | Duration of Charging | About 5 hours | ||

| 14、 | Methods of Remote Control | Radio Frequency 433MHz,3.7V 1500mAh | ||

| 15、 | Remote Controrler | Handheld remote control | ||

| 16、 | Model Control | Handling/Automatic Model | ||

| 17、 | Temperature of Warehouse | -18~40℃ (Normal)/ -30~-18℃(Cryogenic) | ||

| 18、 | Programmable Logic Controller | Siemens PLC | ||

| 19、 | Voltage of Controller Loop | DC 24V | ||

| 20、 | Noise Peak of Running | <70DB | ||

Features of Radio Shuttle Rack

· High-density storage, high warehouse utilization;

· High work efficiency, greatly reducing job waiting time;

· The operation method is flexible, and the access method of the goods can be first-in-first-out or first-in-last-out;

· High safety factor, reduce the collision between racks and forklifts, and improve safety and productivity;

· Relatively low lighting requirements, compared with other types of storage racks, the overall investment is less.

Application of Radio Shuttle Rack

· Large quantity and small sample: food, beverage, chemical industry, tobacco, and other industries with large batches of single varieties and relatively single items;

· Cold storage operation: reduce low-temperature operation time, improve work efficiency and operation safety;

· Time limit management: warehouses that have strict requirements on item batches and require first-in, first-out operation management;

· Increased storage capacity: limited storage space, warehouses that need to maximize the use of space.

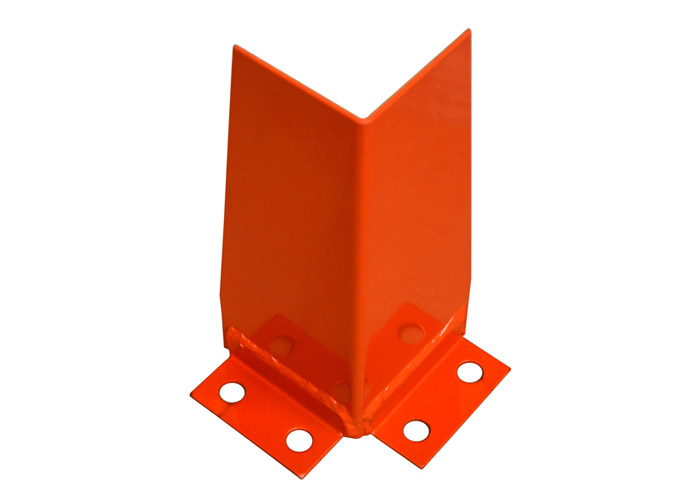

Guide Rail of Radio Shuttle Rack